Carton Freeze & Chill Tunnels

CARTON - air blast system to chill or freeze carton product

Engineers working at food processor

Industrial Solutions

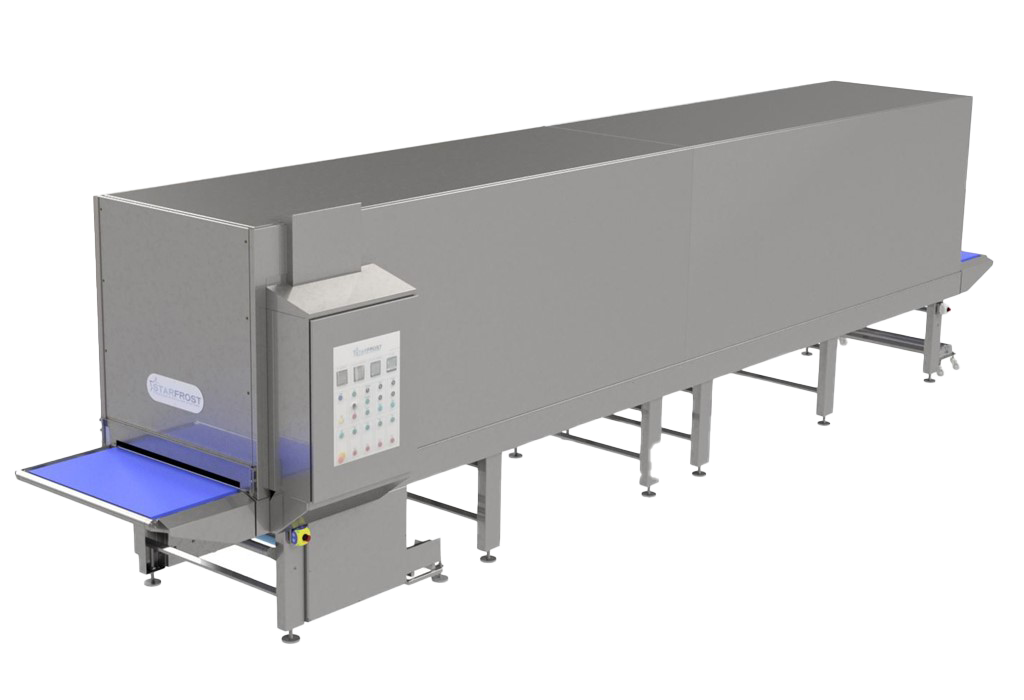

In conjunction with our Australasian partner MHM Automation, Starfrost are able to offer a range of Carton Tunnels for the chilling and freezing of long retention time products. MILMEQ® chillng and freezing tunnels employ an air blast system that provides uniformed conditioning to either chill or freeze product.

The tunnels are available in two distinct designs, the Single Retention Time (SRT) and the Multiple Retention Time (MRT).

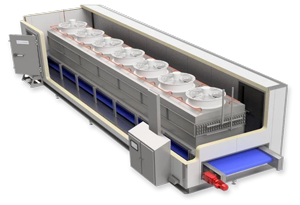

Milmeq Single Retention Tunnel (SRT)

The SRT is designed to accomodate varying product types and carton sizes that require the same chill or freeze time.

It is an air blast based system that provides uniformed conditioning. The SRT can be designed to be either a chill or freeze tunnel. The single retention time, the enclosure temperature and air velocity will be calculated depending on the temperature of product entering the system versus the desired temperature for exit.

The SRT is a first in, first out system which means all cartons complete a full rotation within the system. The carton in feed and out feed conveyors are therefore positioned at one end. These interfacing Materials Handling systems can be multiple levels to increase the load and unload times.

Infeed view of a Milmeq SRT Tunnel – Poultry Chilling Tunnel

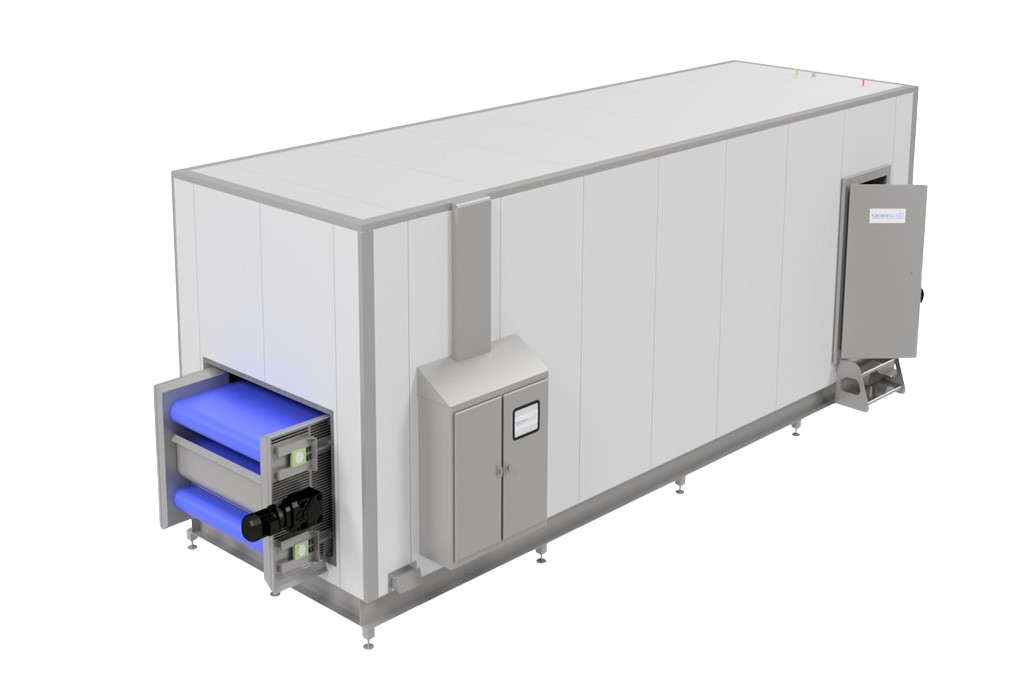

Milmeq Multiple Retention Tunnel (MRT)

The MRT is designed to accomodate varying product types & carton sizes that require diffrerent chill or freeze times.

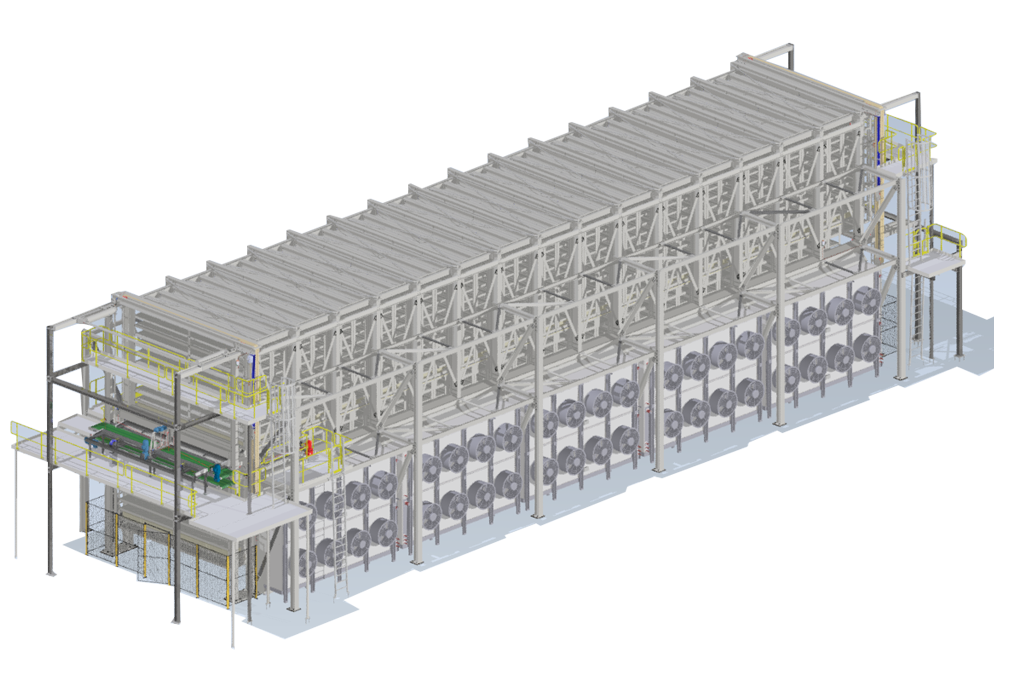

The system is completely automatic.It is an air blast based system that provides flexibility to apply different cooling regimes for groups of product. Depending on the desired conditioning for a product whether it be to chill or freeze, it will be allocated a shelf within the system which has a preset retention time. The allocated shelf will then move the groups of product through the system at a high or low pace and deliver the cartons at the out-feed end of the tunnel.

Cartons of cheddar being loaded into a Milmeq SRT Tunnel – Cheese Cooling Tunnel

External view of Spiral Freezer infeed conveying ready meals

Controls

The integrated controls and automation designed for each system application allows for operator changes to the retention times set. The controls also deliver complete tracking and of all product within the system which aids the management for further processes post chilling or freezing such as palletising and distribution.

The MRT is suited to lower throughput of products within food processing operations that require different conditioning and follow on to customised distribution loads.

Benefits

- Efficient

- Flexible

- Automated

- Bespoke design