The Customer

Iqbal Poultry, a trading arm of Chesterfield Poultry Ltd, supplies the international retail and trade sectors with a variety of poultry products. The firm recently required a chilling system specifically for offal products after expanding its poultry operations at a newly acquired site in Thorne, UK.

The Requirement

The poultry processor’s parent company previously operated water spin chillers, cooling offal products using water submersion, a traditional method used by many offal manufacturers. Iqbal Poultry decided to explore alternative solutions which could offer energy efficiency combined with increased product quality and discovered the significant advantages to cooling with air rather than water.

The Result

Mohammed Fayaz Ahmed, Director at Iqbal Poultry highlights the advantages of the newly installed Starfrost Hybrid Air Chilling Tunnel from Starfrost: “Shifting from water to air chilling was very important to us and the quality of our offal products, so it was essential we had a system designed to specification and able operate at precise temperature requirements; the Starfrost air chilling tunnel system does exactly that.” Fayaz continues “The project with Starfrost has been very successful and we were in safe hands from the start. The air chilling tunnel install has provided us a variety of benefits, primarily the significant improvement to the quality of our offal products; the colouring has been enhanced and shelf life increased so we couldn’t be more satisfied with the end result. “

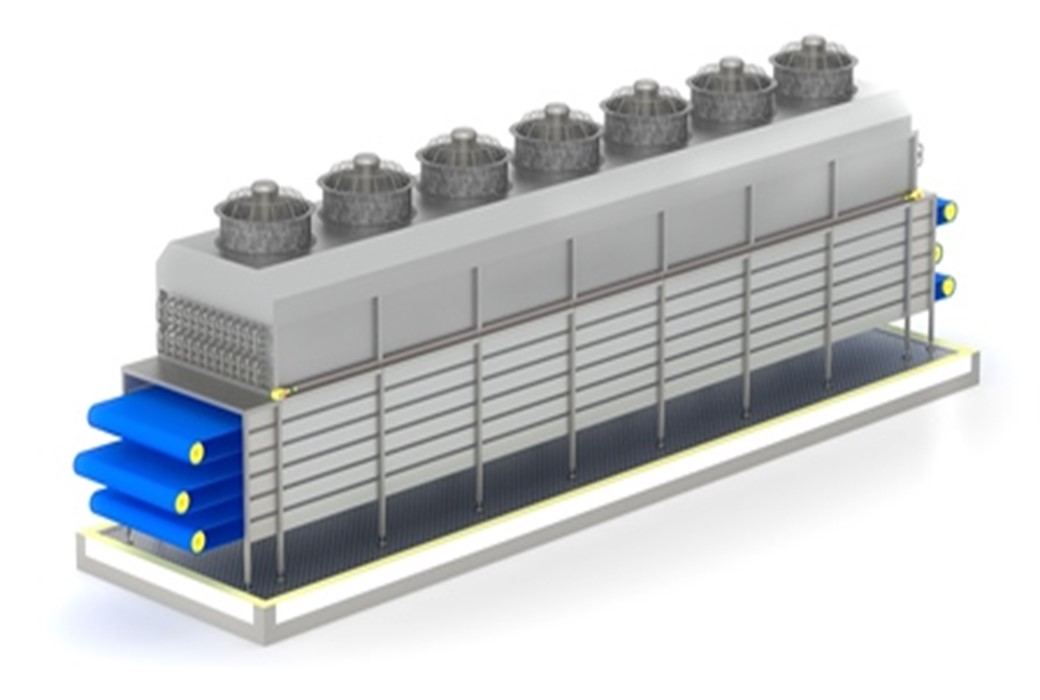

The Solution Iqbal’s chilling tunnel has been designed with an integrated stainless steel belt that simultaneously processes 1200 kilos per hour of heart, liver, gizzards and neck. The system offers the advantage of a self-contained base frame, which enables ease of relocation and flexibility to the customer. The unique, energy efficient design of the Hybrid tunnel allows for operation at a higher air temperature than typically used for chilling, this has enabled Iqbal Poultry to reduce production costs, increase energy efficiency & improve the quality of the offal products. Starfrost’s Hybrid air chilling tunnel offer poultry producers an effective and hygienic design which can reduce the risk of contamination compared to water cooling, whilst maximising product quality. It is designed to offer simple operation, low maintenance and boost operational efficiency.

Iqbal Poultry – Inline Chilling Tunnel for offal products