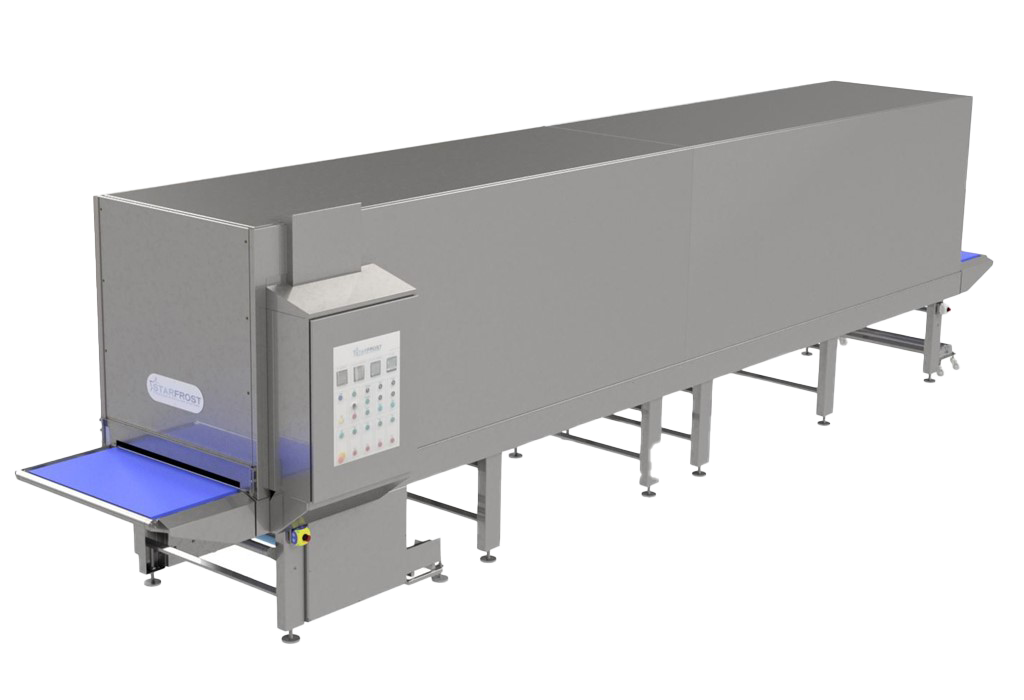

Cryogenic freezing costs too high? Are your operation overheads escalating due to nitrogen price rises? Starfrost can reduce your freezing costs by 90%, with as little as a one year payback.

Pioneers of cooling technology and experts of the food processing industry

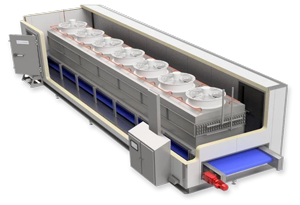

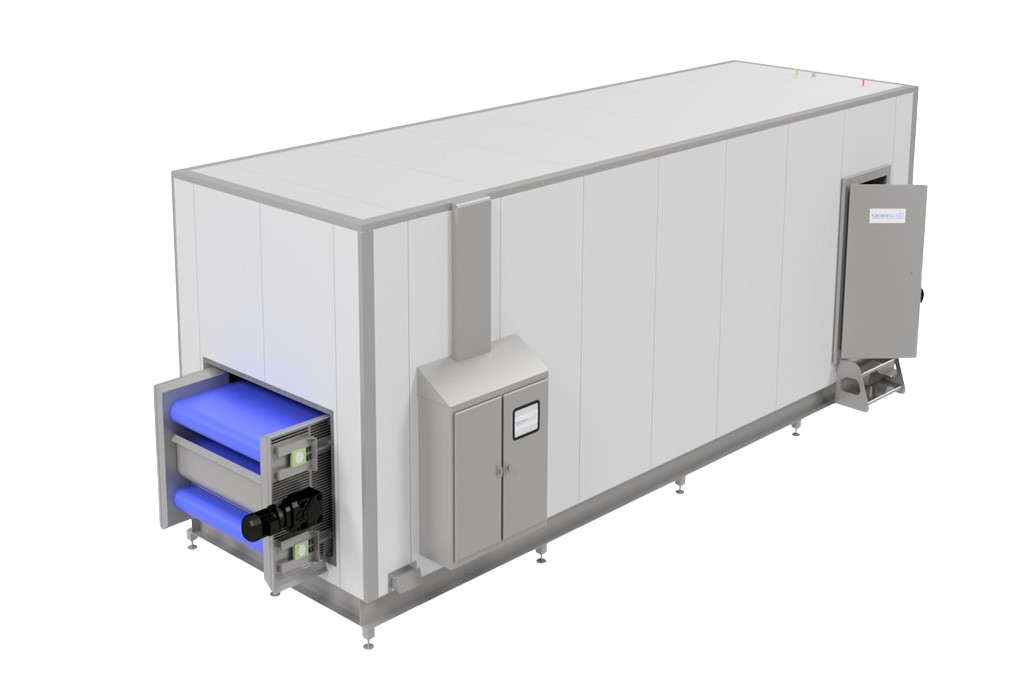

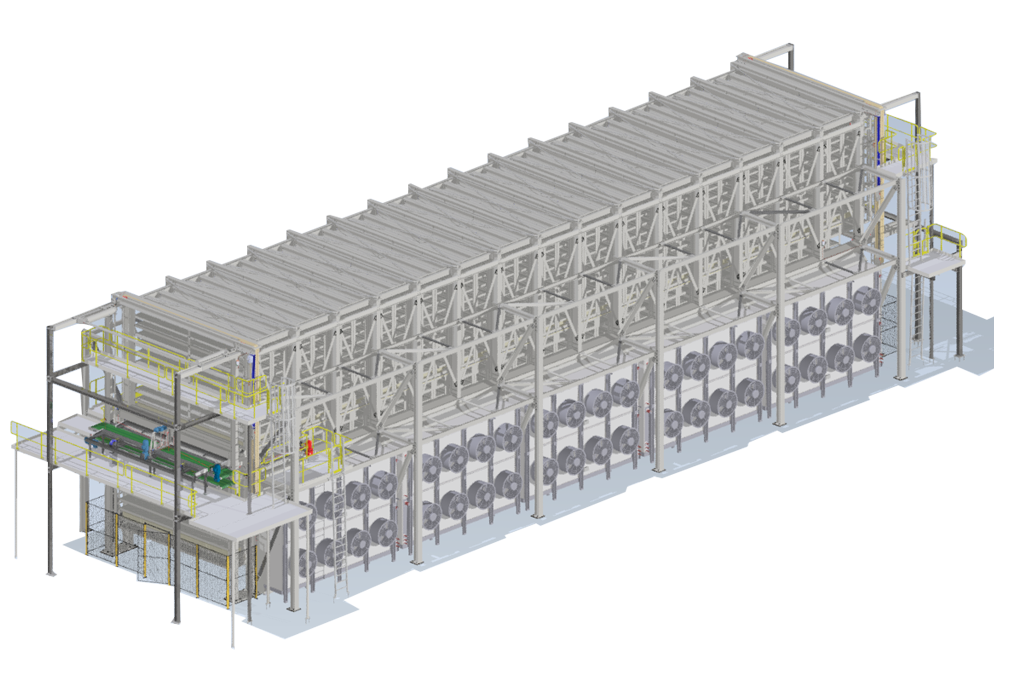

We work in partnership with each of our customers to build bespoke freezing and chilling equipment focused on high performance, reliability and innovation. From installation through to aftercare, our team of experts deliver a wide range of solutions for every food application and all cooling requirements.

Testimonials

Hear what our customers have to say

The importance of consistent, rapid freezing is fundamental to the quality of frozen products, therefore the freezing system and the technology we selected was vital. The new Starfrost system means that we now have the most efficient spiral freezer design combined with high performance freezing.

The results are improved texture and consistency of Mackie’s of Scotland ice cream, as proven in our taste trial results.

With the new compact Starfrost cooling system we were able to upgrade previous system and create space to implement a complete new line within our bakery, without compromising our output capacity.

The number one benefit we have gained from the Helix spiral cooler is repeatable, improved product quality – a result of the consistent temperature airflow. The spiral cooler also removes excess moisture from the loaves, to help improve shelf life.

David Frayling, Area Engineering Manager at Pladis’s site in Halifax

News

Click to view our latest news

New Vacancy: Production Manager

Production Manager Hours: Full time 39 hours per week (Mon – Fri) Salary: £43,000 – £50,000 + generous benefits package Location: Lowestoft About Starfrost Over the last three decades, Starfrost…

New vacancy: Workshop Engineer – Sheet Metal Worker

The Role A new opportunity has arisen for an experienced Sheet Metal Worker to join the Manufacturing team within freezing and chilling equipment manufacturer Starfrost. The position available is working…

Contact us today

To discuss a project, obtain a quotation or to enquire about the services we provide, please get in touch with our team

contactus@starfrost.com

+44 (0) 1502 562206