Rapid

Freezing

High velocity airflow with impingement freezing

Energy

Saving

Extremely low power consumption

Bespoke

Conveyors

Custom designed belt options

Consistent

IQF

Maximises yield for premium IQF products

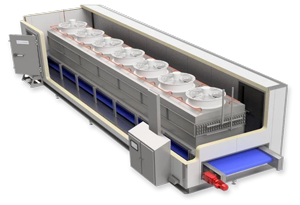

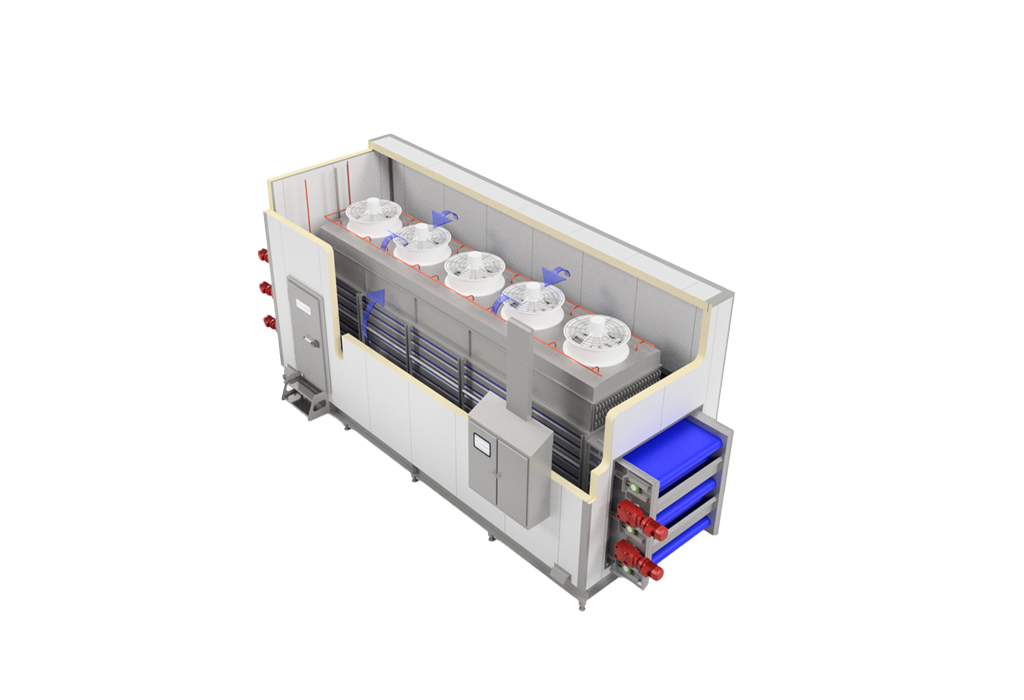

IQF Freezers showing airflow direction

IQF Freezer 3D model internal view

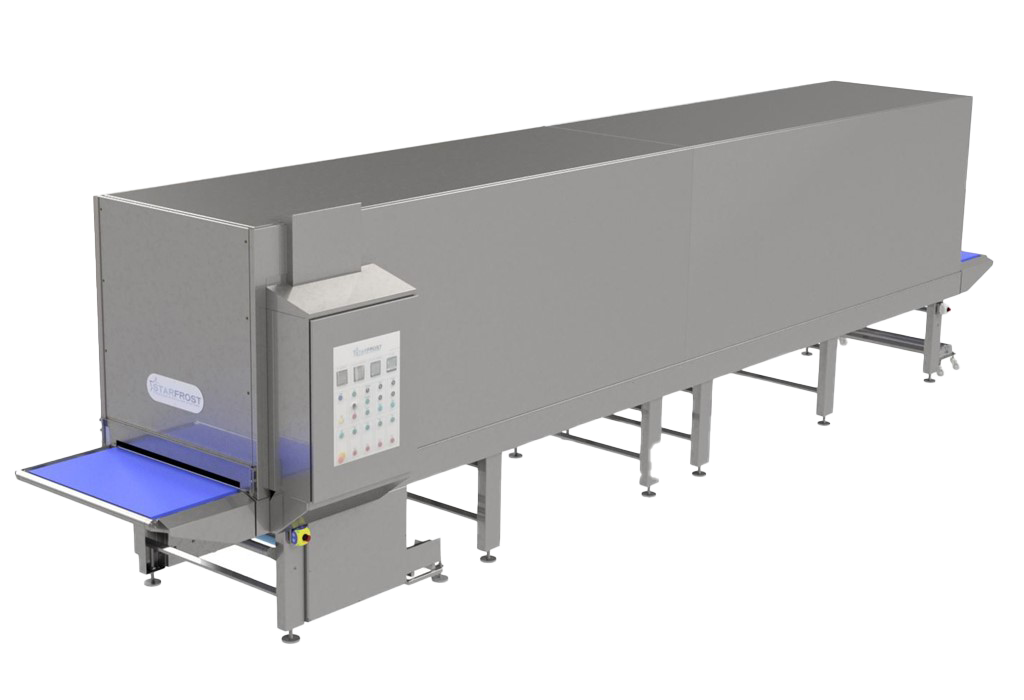

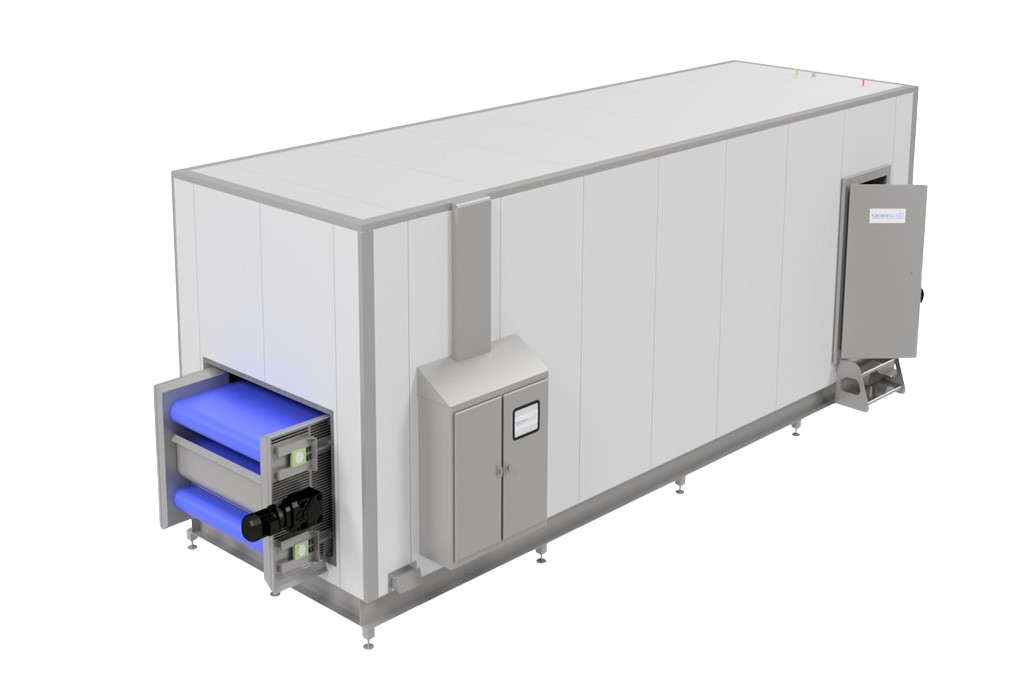

IQF Freezer

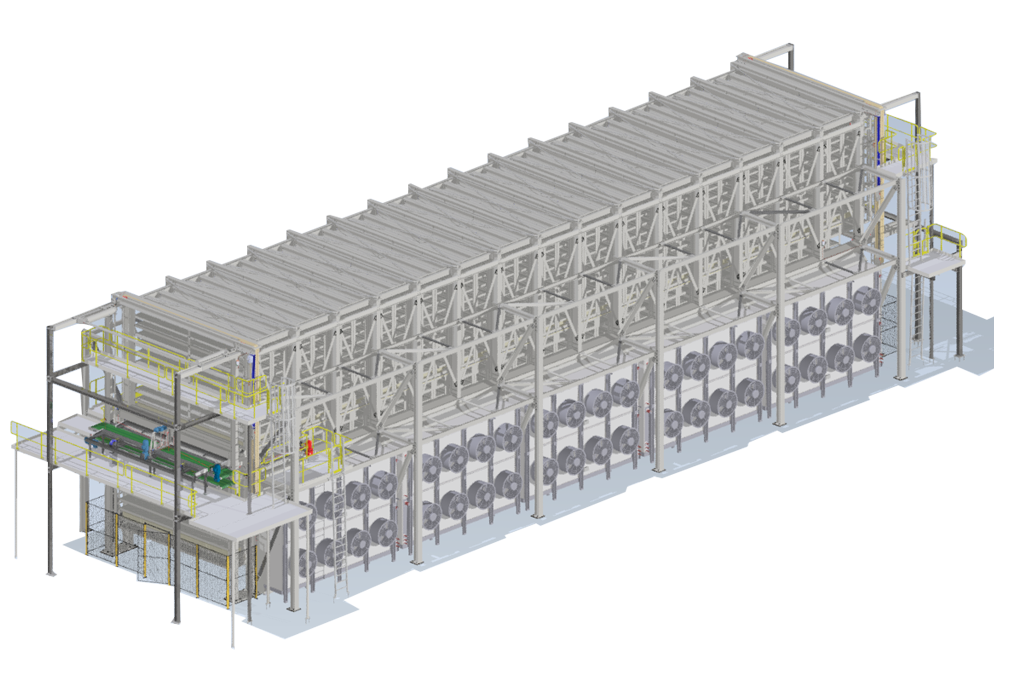

Multibelt IQF Freezer for poultry processor featuring a vibrating infeed bed to ensure product segregation

Flexible Design

The Hybrid is built with flexibility in mind, it can be adapted to freeze, chill, glaze harden and pre cool a wide range of food products including seafood, meat, poultry, bakery, dairy products, fruit and vegetables.

Starfrost Hybrid inline IQF tunnels are a highly versatile IQF systems that combine the design of a Turbo fluidised bed tunnel with the airflow characteristics of a Helix spiral freezer.

Energy Efficient

Advancements in our mechanical freezing technology and design deliver fast freezing and highest quality IQF, this provides food processors a new generation of mechanical freezing equipment.

Removing the requirement for nitrogen freezing, the compact Hybrid IQF Tunnel system delivers extremely rapid and effective freezing times at significantly lower costs than cryogenic freezing, with a typical 18-month payback when compared to a cryogenic freezer.

External view of IQF Freezer installed at UK meat manufacturer

Bespoke Solutions

The single or multi belt design provides an ideal solution for upgrading from static blast freezing to progress to continuous in-line IQF processing, or for diversifying or expanding production.

Custom Built

In addition to rapid continuous automated cooling, the Hybrid can be custom designed for the glaze hardening of delicate products. The glaze hardening process increases yield, preserves texture and flavour of delicate products together with eliminating damage for maximised product quality and shelf life.

External view of IQF Freezer out-feed conveyor belt

Features

- Fast and efficient cooling with multiple level conveyor belts

- Belts can operate independently at various speeds or on a cascade principle

- Adjustable air speed for controlled processing of light and delicate products

- Full freezing up to 600 kg/hr and chilling, hardening or re-freezing to in excess of 4,000 kg/hr

- Cost effective alternative to running a cryogenic nitrogen tunnel freezer

Benefits

Low maintenance

With a fully accessible stainless steel design

Efficient

Design provides rapid freezing with extremely low power consumption

Rapid freezing

Dual direction air delivering the fastest freeze process available

Bespoke belt options

Conveyors can operate independently at various speeds or on a cascade principle

Air technology

Adjustable air speed for controlled processing of light and delicate products